| IN A NUTSHELL |

|

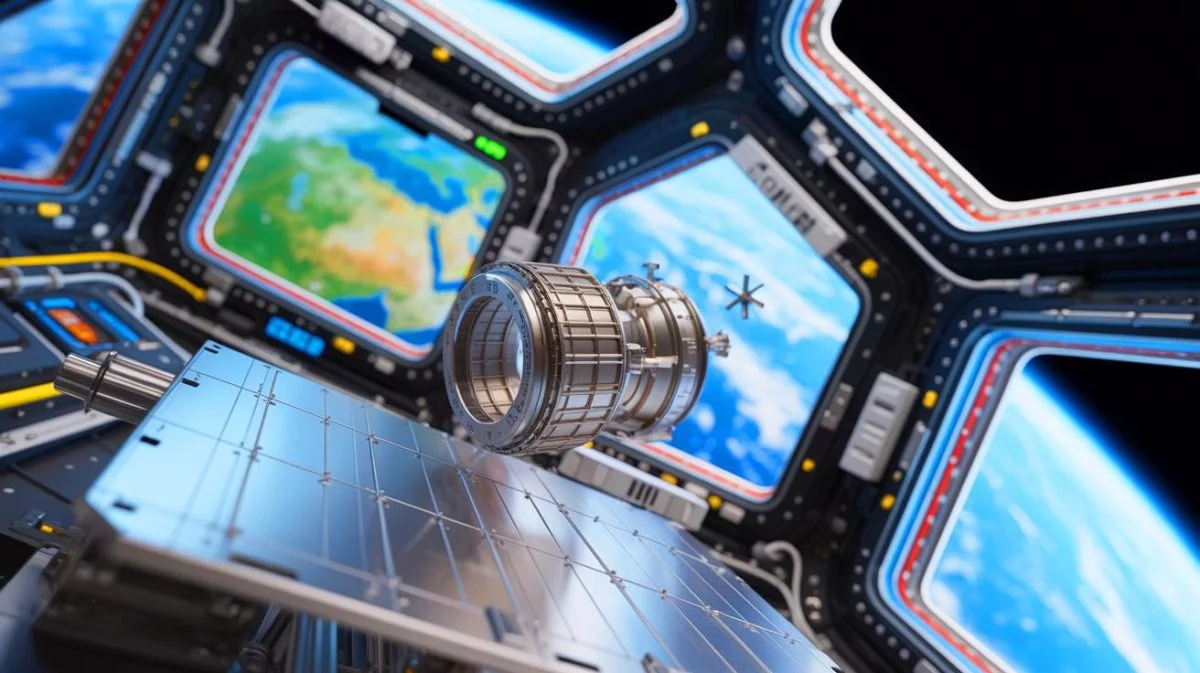

In a landmark development, scientists at the European Space Agency (ESA) have achieved a breakthrough in space technology by successfully creating a metallic object in space using a 3D printer aboard the International Space Station (ISS). This pioneering endeavor, in collaboration with Airbus Defence and Space, signifies a significant leap in space exploration capabilities. The ability to manufacture essential components directly in space could potentially alter the landscape of future missions, reducing dependency on Earth-bound supply chains and enabling more sustainable space operations. This article explores the intricacies and implications of this innovative technology.

The First Metallic Object Created in Space

The recent achievement by the ESA marks a historic milestone in space exploration. For the first time, a metallic object was produced entirely in space using a metal 3D printer aboard the ISS. This printer, developed with Airbus Defence and Space, was operated by astronaut Andreas Mogensen in the Columbus module. The initial test involved printing an ‘S’ curve, followed by the successful creation of two complete samples. This momentous accomplishment underscores the advancing capabilities of 3D printing technology in the unique environment of space.

The implications of this success are profound. By refining our understanding of how microgravity influences the 3D printing process, scientists can enhance this technology for upcoming missions. The ability to produce tools and components on-demand in space could significantly decrease reliance on supply missions from Earth. This development could lead to more sustainable and autonomous operations in space, paving the way for long-term habitation and exploration beyond our planet.

The Role of Microgravity in 3D Printing

An essential aspect of ESA’s research involves understanding the effects of microgravity on 3D printing. Unlike on Earth, where gravity assists in material deposition, space presents unique challenges due to the absence of gravity. Metal powders used in 3D printing behave differently in microgravity, necessitating specialized systems to manage and direct these materials precisely.

The technology employed in space mirrors terrestrial 3D printing techniques, utilizing a laser to melt metal powder layer by layer to create solid objects. However, adapting these techniques for space requires significant innovation in both materials and design. This adaptation is crucial for future missions, where on-demand production of parts could offer substantial logistical and economic benefits. The ability to print components in space could revolutionize the way missions are planned and executed, with implications for both near-Earth and deep space exploration.

Implications for Future Space Missions

The successful implementation of 3D metal printing technology in space holds transformative potential for the future of space exploration. By enabling the in-situ production of spare parts and tools, missions can attain greater self-sufficiency, reducing dependency on Earth-based resupply missions. This self-sufficiency is especially crucial for deep space exploration, where resupply from Earth is neither feasible nor cost-effective.

Looking forward, the advancement and application of this technology could lead to more ambitious projects, such as constructing entire structures in orbit. These developments could reshape our approach to space infrastructure and exploration, making long-term habitation and missions more viable. Additionally, this technology exemplifies the power of collaboration between space agencies and industry leaders to push the boundaries of what is possible in space exploration.

Challenges and Innovations in Space-Based 3D Printing

While the potential benefits of space-based 3D printing are immense, challenges remain. Developing printers capable of functioning in the harsh conditions of space requires substantial innovations in design and materials. The systems must withstand unique environmental factors such as radiation and extreme temperature fluctuations.

Moreover, the precision needed to manage and manipulate metal powders in microgravity demands cutting-edge technological solutions. Despite these challenges, the ability to produce components on-demand in space marks a significant leap in space technology. By sending digital plans from Earth, astronauts can manufacture necessary items as required, reducing the logistic burden of carrying an extensive inventory of spare parts.

This groundbreaking technology raises crucial questions about the future of space exploration and habitation. How will advancements in 3D printing technology change our approach to colonizing other planets? Could this innovation unlock new possibilities for human life beyond Earth? The answers to these questions could define the next chapter of human exploration into the cosmos.

Did you like it? 4.5/5 (28)

Wow, this is like something out of a sci-fi movie! 🚀

Are they sure it’s not alien tech? Seems too advanced to be human-made. 👽

This could revolutionize the way we do space missions. Imagine the possibilities!

How long until we can start printing whole space stations in orbit?

Next step: building a moon base with 3D printing! 🌕

Does this mean we can finally have a 3D-printed pizza in space? 🍕

What kind of metal was used in the printing process?

Is this technology safe to use in the long term, considering space conditions?