| IN A NUTSHELL |

|

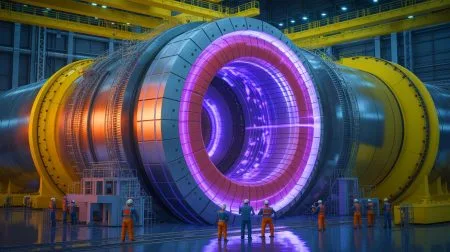

The United Kingdom is rapidly advancing in the field of fusion energy with the introduction of cutting-edge technology that promises to revolutionize reactor components. The UK Atomic Energy Authority (UKAEA) has unveiled two state-of-the-art 3D printing machines designed to withstand the extreme conditions of fusion power plants. Located at the newly opened Central Support Facility, these machines are set to transform the production of fusion reactor parts, facilitating a future where clean, sustainable energy is within reach.

Inside the New Facility

The Central Support Facility has become a hub of innovation with the commissioning of two advanced 3D printers. These machines, designed by Freemelt and Nikon SLM Solutions, utilize additive manufacturing techniques that are crucial for producing intricate designs required in fusion reactors. Additive manufacturing allows for the production of highly specialized, custom components in small volumes, making it ideal for the unique needs of fusion energy systems. According to UKAEA’s Roy Marshall, these technologies are essential for achieving the complex material combinations and precise engineering necessary for future fusion power plants.

The eMELT Electron Beam Powder Bed Fusion system operates by fusing tungsten powder into near-solid components, achieving nearly 100 percent density. This method is crucial for producing parts that face the plasma in fusion reactions, where temperatures soar to extreme levels. Meanwhile, the SLM280 Selective Laser Melting machine explores complex geometries and material combinations, reducing reliance on traditional manufacturing techniques such as welding. By minimizing the number of manufacturing steps, these machines not only enhance efficiency but also lower production costs.

Clean Energy Starts With Fusion

The role of fusion energy in achieving a sustainable future cannot be overstated. With the potential to provide a nearly limitless source of clean energy, fusion represents a beacon of hope in the fight against climate change. The UKAEA’s new 3D printing machines are at the forefront of this transformation, demonstrating that fusion components can be produced at scale. This capability is a game-changer, as it makes the development of complex fusion parts more commercially viable.

3D printing technology reduces the costs associated with precision manufacturing, making it a more attractive option for the industry. The ability to produce components with both electron beam and selective laser technologies under one roof is unprecedented in the fusion sector. As the machines begin to conduct experiments and assess the properties of additively manufactured materials, the fusion industry moves closer to realizing its full potential. As Christoph Barefoot of Nikon SLM Solutions aptly stated, “Fusion represents the future of energy – but it can only be realized through bold innovation and trusted collaboration.”

Key Technologies and Their Impact

The eMELT Electron Beam Powder Bed Fusion system and the SLM280 Selective Laser Melting machine are pivotal in addressing the manufacturing challenges of fusion reactors. The electron beam system, designed by Freemelt, is particularly suited for layering tungsten onto other metals such as copper chrome zirconium and stainless steel, materials essential for the durable components required in fusion environments. The laser melting machine, supplied by Kingsbury Machine Tools, focuses on achieving complex geometries, which are crucial for optimizing the performance of fusion parts.

These technologies collectively enable the production of components with enhanced resilience to the harsh conditions of fusion reactors, characterized by high heat, intense neutron loads, and strong magnetic fields. By streamlining the manufacturing process and reducing the need for multiple production steps, these machines are poised to significantly lower the barrier to entry for companies looking to invest in fusion energy. This innovative approach not only bolsters the viability of fusion as a mainstream energy source but also underscores the importance of technological advancements in overcoming the hurdles of traditional manufacturing methods.

The Future of Fusion Energy

As the world continues to grapple with the challenges of climate change and energy sustainability, fusion energy emerges as a promising solution. The UKAEA’s commitment to advancing fusion technology through the use of 3D printing marks a significant milestone in the journey towards clean energy. By fostering innovation and collaboration across industries, the UK positions itself at the forefront of this transformative field.

As the new 3D printing machines pave the way for more efficient and cost-effective production of fusion reactor parts, the potential for fusion energy to become a mainstream energy source grows ever closer. Will the lessons learned from these advancements in the UK serve as a catalyst for the global adoption of fusion energy, and what challenges remain on the horizon?

Did you like it? 4.7/5 (23)

Wow, this is amazing! Could fusion energy finally be the answer to our energy problems? 🌍✨

I’m not convinced that 3D printing can handle the extreme conditions of a fusion reactor. Anyone else skeptical?

Thank you for sharing this! It’s exciting to see the UK leading in fusion technology. 💪🇬🇧

How long until we see these reactors actually being used in the real world?

The technology sounds promising, but what about the cost? Will it be affordable for widespread use?

3D printing in fusion energy? That’s a game-changer! 🎮

This is all well and good, but will it be enough to combat climate change in time?

Fusion energy sounds great, but what are the risks involved with these new technologies?

I’m curious about the environmental impact of producing these 3D printed components. 🤔